The “Sembang AIoT” live session took place on March 29, 2024. Once again, the Axiomtek Malaysia AIoT Team shared insights into fog computing and its role in enhancing both Edge and Cloud computing for the Industrial IoT ecosystem.

Why is fog computing crucial in the construction of the entire industrial transformation system? Why does it often receive less attention in digital transformation infrastructure discussions?

Fog computing serves as an intermediary layer that shares similarities with both edge devices and cloud servers. However, upon closer examination, it emerges as a valuable enhancer and complement to Edge and Cloud computing.

Why fog computing in Smart Manufacturing:-

Real-time Data Processing: In smart manufacturing, numerous sensors and devices generate vast amounts of data. Fog computing enables the processing of this data in real-time, allowing for immediate insights and decision-making at the edge of the network. This real-time processing is critical for optimizing production processes, predicting equipment failures, and ensuring quality control.

Low Latency: Smart manufacturing applications often require low-latency communication to respond quickly to events on the factory floor. Fog computing brings computing resources closer to the edge devices, reducing the latency associated with transmitting data to centralized cloud servers for processing. This low-latency communication is essential for tasks such as machine control, robotics, and safety monitoring.

Scalability: Fog computing allows for distributed computing resources that can scale according to the needs of the manufacturing environment. As the number of connected devices and sensors grows, fog nodes can dynamically allocate computing and storage resources to handle the increased workload. This scalability ensures that smart manufacturing systems can adapt to changing production demands without sacrificing performance.

Reliability: Smart manufacturing environments require reliable and resilient computing infrastructure to maintain continuous operations. Fog computing provides redundancy and fault tolerance by distributing computing tasks across multiple fog nodes. In the event of a network outage or hardware failure, nearby fog nodes can continue processing data and executing tasks, minimizing downtime and disruptions to production processes.

Data Privacy and Security: Fog computing can address concerns related to data privacy and security in smart manufacturing. By processing sensitive data locally at the edge of the network, fog nodes can reduce the need to transmit sensitive information over the internet to centralized cloud servers. This localized data processing helps mitigate security risks and ensures compliance with data protection regulations.

Overall, fog computing enhances smart manufacturing by enabling real-time data processing, reducing latency, providing scalability and reliability, and addressing privacy and security concerns. It serves as a critical component in building agile, efficient, and resilient manufacturing systems for the Industry 4.0 era.

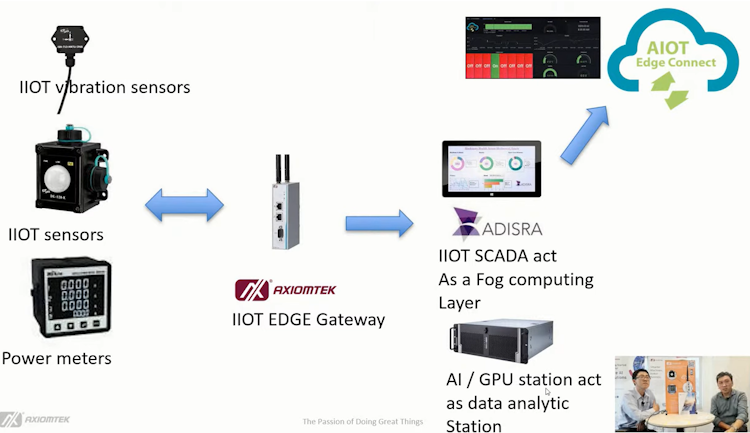

Demonstration on the SCADA server on Axiomtek Rackmount server that act as a distributed data collection and decentralized monitoring and analytic platform. It complements the Edge and Cloud computing in providing a low latency interaction with the actual process.

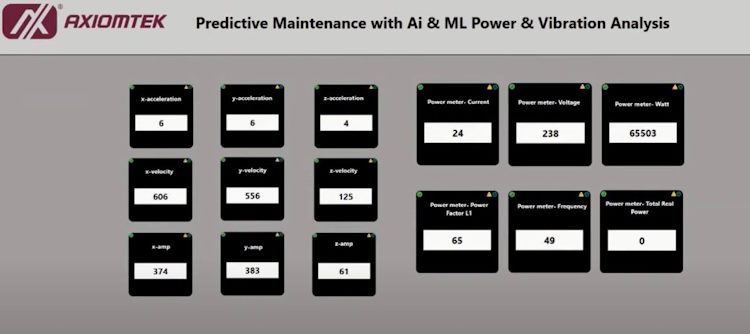

The edge gateway captures power meter data and vibration data, which is then transmitted to the Adisra SCADA server for presentation and manipulation with minimal latency, ensuring a more real-time experience.

Beside OEE tracking with AIoT to improve the efficiency of the manufacturing process, avoiding downtime can be crucial to make sure the OEE is at the optimize level. So, the right maintenance process like predictive maintenance can be one of the option where Fog computing is neccessary.

One example of fog computing in smart manufacturing involves the implementation of predictive maintenance systems. In this scenario:

Data Collection: Sensors installed on manufacturing equipment continuously collect data on various parameters such as temperature, vibration, and operating conditions.

Edge Processing: Instead of sending all raw data to the cloud for analysis, fog nodes located near the manufacturing equipment perform initial data processing and filtering at the edge. This process includes filtering out irrelevant data and identifying patterns or anomalies that may indicate potential equipment failures.

Local Analysis and Decision-making: The fog nodes analyze the processed data locally and compare it against pre-defined thresholds or machine learning models trained to detect early signs of equipment degradation or failure. If a potential issue is detected, the fog node can trigger immediate actions such as sending alerts to maintenance personnel or adjusting equipment settings to prevent further damage.

Reduced Latency: By performing data processing and analysis at the edge, fog computing reduces latency and enables faster response times compared to sending data to centralized cloud servers for analysis. This is crucial for real-time decision-making in smart manufacturing environments where even minor delays can impact production efficiency and equipment uptime.

Cloud Integration: While fog nodes handle real-time processing and decision-making, relevant data or insights can still be sent to the cloud for further analysis, long-term storage, and integration with other enterprise systems. Cloud-based analytics can provide deeper insights into equipment performance trends, optimize maintenance schedules, and support overall process optimization initiatives.

By leveraging fog computing in predictive maintenance systems, smart manufacturing companies can improve equipment reliability, reduce unplanned downtime, and optimize maintenance costs, ultimately leading to increased productivity and profitability.

To watch our live session click at the link below:-

https://youtube.com/live/2TIgeE6Yl0w

Axiomtek Malaysia (AXMY) emerges as the premier provider of industrial computer systems and a leading AIoT partner in Malaysia.

As a key player in the Southeast Asian industrial computing and embedded systems sector, AXMY operates under a franchised partner program with Axiomtek Taiwan. This collaboration ensures swift local support and specialized expertise, enabling AXMY to deliver customized solutions across diverse industrial computing domains.

Dedicated to innovation, we continually develop cutting-edge devices and solutions in the AIoT realm, making them accessible and cost-effective for various industries. Our commitment extends to sharing the latest technological advancements in industrial transformation, catering to all levels of expertise within the context of Industry 4.0 and digital transformation initiatives.