This session of ” Sembang AIoT” talk more about the integrating IIoT and AI for optimal performance of industry 4.0 performance.

Industry 4.0 (IR4) is the current trend of automation and data exchange in manufacturing technologies, encompassing cyber-physical systems, the Internet of Things (IoT), cloud computing, and cognitive computing. Here are the four main design principles of Industry 4.0:

- Interconnection

- Decentralization

- Data Transparency

- Technical Assistant

There are many processes that require IOT and AI, Four major implementations that deploy IIoT and AI in the manufacturing as belows:-

- Real-time Data Collection and Analysis: IoT devices, such as sensors and actuators, can continuously gather data from the production floor. AI algorithms can then process this vast amount of data in real-time to detect anomalies, predict failures, and offer insights.

- Predictive Maintenance: Using data from IoT devices, AI can predict when machinery and equipment are likely to break down or require maintenance. This means that instead of periodic maintenance schedules, maintenance can be performed just in time, reducing downtime and saving costs.

- Quality Assurance: Cameras and sensors can detect manufacturing defects. AI can then process this data to automatically identify and classify defects, ensuring consistent product quality and reducing the need for manual inspections.

- Energy Management: IoT sensors can monitor energy consumption in real-time, and AI can optimize energy usage, making recommendations for energy-saving or even automatically adjusting processes to be more energy-efficient.

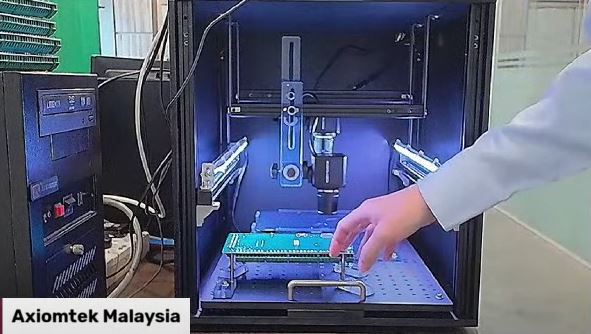

This session is further enhanced with the properly set demonstration on the un supervised Deep learning anomaly detection system. Axiomtek’s Fanless industrial PC is used in this deployment of demo. In order to speed up the inference process, one of the Entry level GPU is used to keep up with performance.

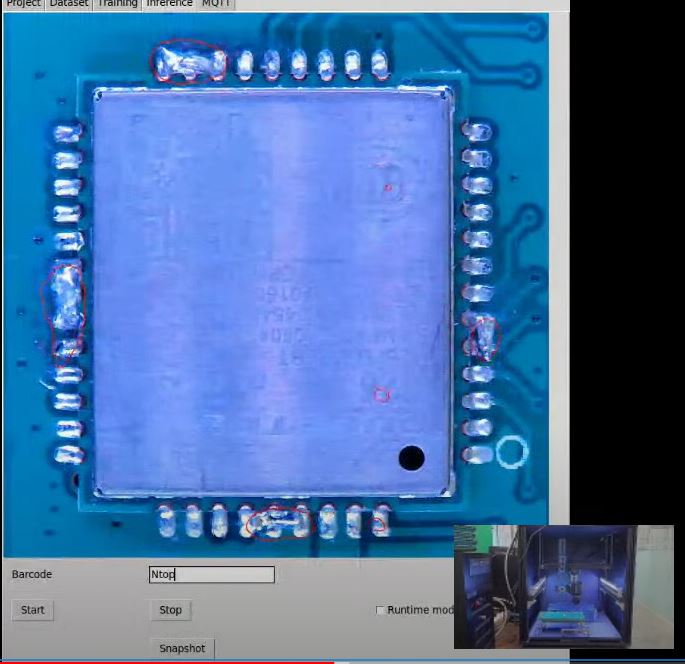

The unsupervised deep learning AI in this model do not require any intervention on the dataset that are used. Good dataset or samples are fed and with minimum work on the result that we need to achieve. We took one of the good example of Printed Circuit Board ( PCB) visual inspection process where the time required to check on the PCB takes about 45 seconds per board. But with Vision anomaly AI, It took only 2 seconds on the entire PCB with 4 to 6 cameras depending on the size of the PCB.

The picture on the left show the visual image of marked red AI spotted unwanted soldered joined and those images can be marked and stored as part of the defect listing.

Different zones of defects can be recorded for the next process of rework.

- Unsupervised Learning: In traditional machine learning, unsupervised learning refers to training algorithms without any labeled data. The most common applications are clustering (grouping data in categories based on their similarity) and dimensionality reduction (reducing the number of variables in a dataset while preserving its structure or distribution).

- Deep Learning: Deep learning is a subset of machine learning that deals with algorithms called neural networks, particularly deep neural networks. These networks are capable of learning complex patterns from large amounts of data. “Deep” refers to the number of layers in the network; the more layers, the deeper the network.

To watch the entire sharing on Youtube and we appreciate if you can follow us by subscribing to the channel. Thank you.

https://www.youtube.com/watch?v=y3E-HUiDD3w

The IPC962-525 is a 2 slots Robust fanless industrial PC system powered by the LGA1151 Socket 9th/8th generation Intel® Core™ processor (code name: Coffee Lake and Coffee Lake Refresh) with the Intel® H310 chipset or Intel® Q370 chipset. The IPC962-525 has an optional extension I/O module slot with four choices of I/O modules including AX93511, AX93516, AX93519 and AX9351 including a GPU in this case.

AIOT Workshop Awaiting!

Workshop from now till end of 2023! . We are offering a 2 hours Free online AIoT workshop.

You may scan in QR code to kick start your AIoT journey!

We encourage business owners who would like to enhance build a better value in your business with new technology!

In the consideration of unemployed fresh Graduate, You are welcome to register, we will have other technical sharing session for you guys to enhance your knowledge in this set of technology for a better career opportunity.