Join us for a live session hosted by Axiomtek Malaysia, your premier AIoT partner, on March 22, 2024. Discover the immense value of data in shaping the future, particularly in the context of commoditizing or monetizing your data right at your shop floor, especially within the manufacturing process.

In the age of digitization, with advancements in AI and IoT technologies, datasets are gaining unprecedented utility. The availability of robust computing power enables deep data analytics and machine learning, enhancing the value of data sets. Those who have diligently maintained their historical data stand at a significant advantage, as they can leverage this data to optimize their processes with AI assistance. Moreover, such data holds immense value for others engaging in similar processes or initiating startups in related domains, as they can learn from and kickstart their operations with pre-trained AI models, ensuring optimal efficiency from the outset. So, the chances that the data can be sold later to interested party.

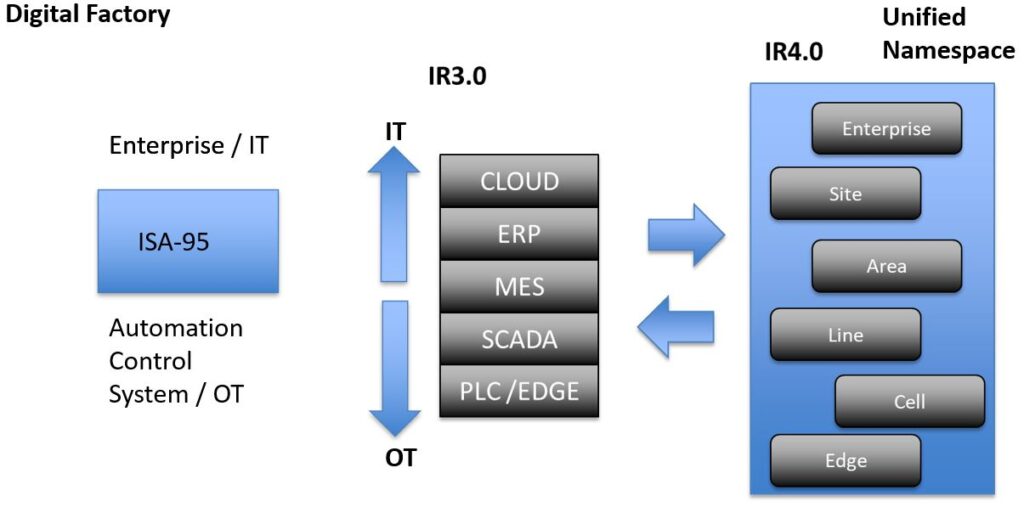

ISA-95, also known as ANSI/ISA-95 or ISA-95, is an international standard developed by the International Society of Automation (ISA) that defines models and terminology for the integration of enterprise and control systems. It provides a framework for integrating business and manufacturing operations, particularly in industrial automation and control systems.

The importance of ISA-95 in the context of Industry 4.0 lies in its ability to facilitate seamless communication and interoperability between different levels of manufacturing systems. Here’s why it’s significant:

Standardization: ISA-95 establishes a standardized terminology and framework for communication and integration between enterprise resource planning (ERP) systems at the business level and manufacturing execution systems (MES) and control systems at the operations level. This standardization ensures consistency and compatibility across systems and enables easier integration of disparate systems.

Interoperability: By defining common models and interfaces, ISA-95 enables interoperability between different systems and components within a manufacturing environment. This interoperability is crucial for Industry 4.0 initiatives, where the integration of various technologies, such as IoT devices, cloud computing, and data analytics, is essential for achieving seamless and efficient operations.

Data Exchange: ISA-95 facilitates the exchange of data and information between different layers of the manufacturing hierarchy. This includes data related to production schedules, equipment status, quality control, inventory management, and more. In the context of Industry 4.0, where data-driven decision-making is paramount, ISA-95 helps ensure that relevant data is available where needed and in a format that can be easily utilized for analysis and optimization.

Efficiency and Agility: By providing a standardized framework for integrating business processes with manufacturing operations, ISA-95 helps improve overall efficiency and agility in the manufacturing environment. It enables real-time visibility into production processes, better coordination between different departments, faster response to changing market demands, and improved decision-making based on timely and accurate information.

In summary, ISA-95 plays a crucial role in enabling the integration, interoperability, and data exchange required for Industry 4.0 implementations. It provides a solid foundation for leveraging advanced technologies and methodologies to drive innovation, efficiency, and competitiveness in modern manufacturing environments.

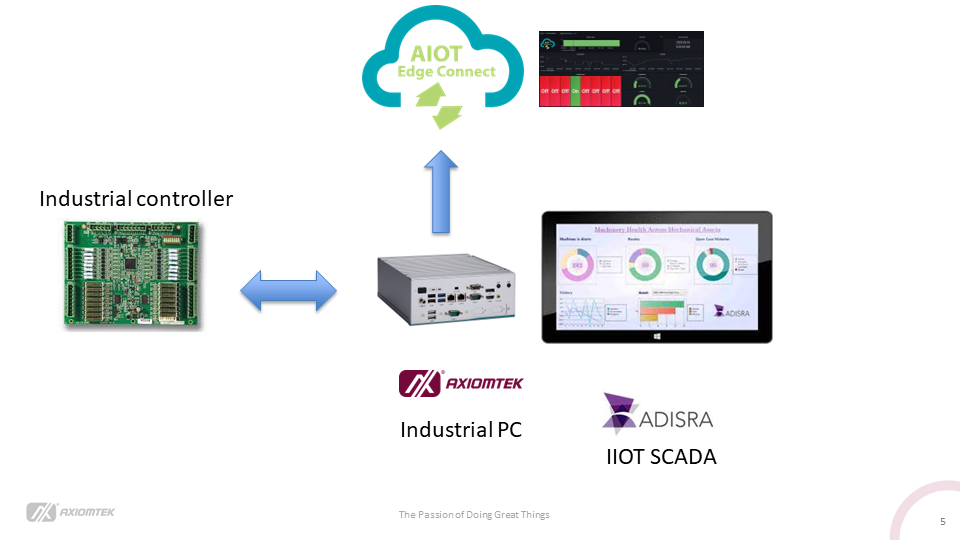

Demonstration on IIoT SCADA in serial based Data acquisition

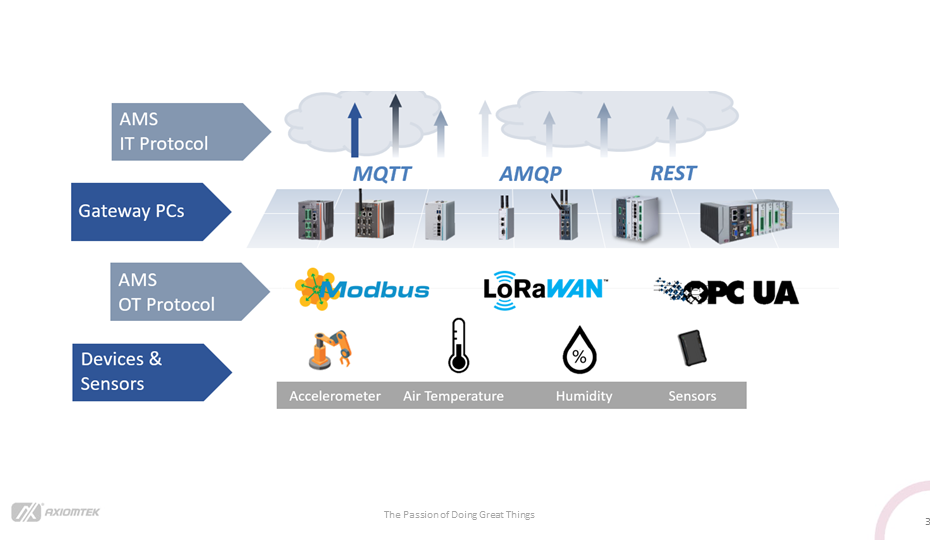

During the session, the Axiomtek Malaysia AIoT Team showcased a demonstration of serial-based data acquisition using a IIoT SCADA Tool called AdisRa. At many shop floors, proprietary equipment generates vital data crucial for decision-making. The issue addressed in this demonstration is the transmission of serial communication data in substandard protocols. To resolve this challenge, the use of an appropriate software tool is essential, aided by the IIoT SCADA tool, Adistra, which incorporates a standard built-in driver for handling serial data. Data capture is achieved through configuration and simple scripting in C#. Subsequently, the data can be stored in historical trending charts and, significantly, can be published via the standard MQTT protocol for smart manufacturing to either the cloud or an on-premise Cloud Edge Server. In cases where you are dealing with the unattended remote site, The 4G IIOT gateway router can also be the solutions.

There is another article showing the demonstration on Cloud in AIoT for Smart manufacturing. you may also want to check this out here.

Axiomtek Malaysia (AXMY) emerges as the premier provider of industrial computer systems and a leading AIoT partner in Malaysia.

As a key player in the Southeast Asian industrial computing and embedded systems sector, AXMY operates under a franchised partner program with Axiomtek Taiwan. This collaboration ensures swift local support and specialized expertise, enabling AXMY to deliver customized solutions across diverse industrial computing domains.

Dedicated to innovation, we continually develop cutting-edge devices and solutions in the AIoT realm, making them accessible and cost-effective for various industries. Our commitment extends to sharing the latest technological advancements in industrial transformation, catering to all levels of expertise within the context of Industry 4.0 and digital transformation initiatives.