The Plugfest programs, organized under the Electrical and Electronics Productivity Nexus (EEPN) and managed by the Malaysia Productivity Corporation (MPC), have been instrumental in advancing Malaysia’s push toward Industry 4.0. These programs were designed to help small and medium enterprises (SMEs) and industrial players adopt cutting-edge technologies such as the Industrial Internet of Things (IIoT) and Artificial Intelligence (AI) to optimize their operations.

The two key iterations of the program—Plugfest 1.0 and Plugfest 2.0—focused on providing hands-on training in these technologies, resulting in significant Proof-of-Concepts (POCs) that could be applied in real industrial environments. Throughout these programs, Axiomtek’s hardware and software platforms played a crucial role in delivering the technological infrastructure needed for AI and IoT solutions.

Plugfest 1.0 industrial IoT

Plugfest 1.0: Introducing IIoT to Malaysian Industries

Objective: Plugfest 1.0 focused on providing training in the Industrial Internet of Things (IIoT), introducing participants to the core concepts of sensor-based connectivity, real-time data acquisition, and industrial monitoring.

Key Technologies:

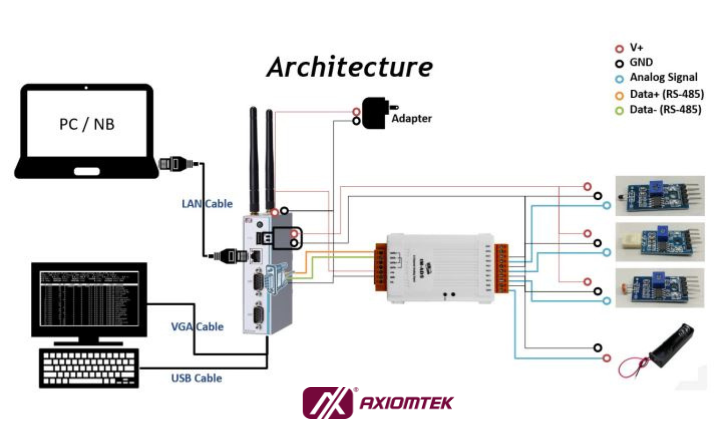

Participants were introduced to sensors (light, temperature, humidity) and learned to connect these to an analog-to-digital converter (ADC) linked to an Internet gateway.

They were trained in Node-RED programming, which allowed them to visualize data from sensors and create interactive dashboards, enabling real-time monitoring and control of various industrial environments.

Axiomtek’s Contribution:

Axiomtek‘s high-performance industrial PCs and edge computing platforms were integral to the program, providing the computational power needed to handle sensor data processing and visualization.

The reliability and scalability of Axiomtek’s hardware ensured that participants could experience seamless integration of sensors into industrial systems, reinforcing the practical applications of IIoT in smart factories.

Impact and Results:

Companies that participated in Plugfest 1.0 were able to develop POCs that allowed them to monitor environmental factors such as temperature, humidity, and light in their production processes. This resulted in improved product quality control and operational efficiency.

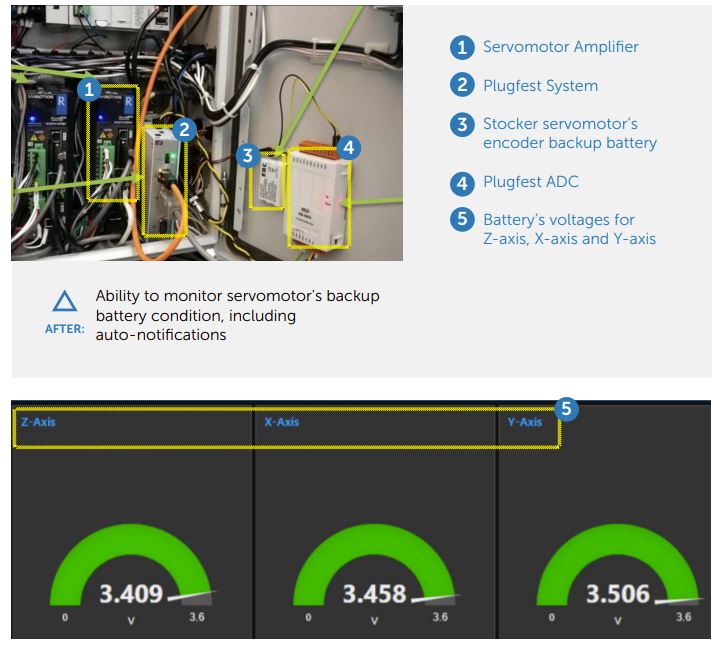

For example, companies could remotely monitor critical machinery conditions and automate alerts for preventive maintenance, reducing equipment downtime and boosting productivity.

Referring to the Net Zero program, the IIoT is best used in monitoring energy with instruments like a Power meter.

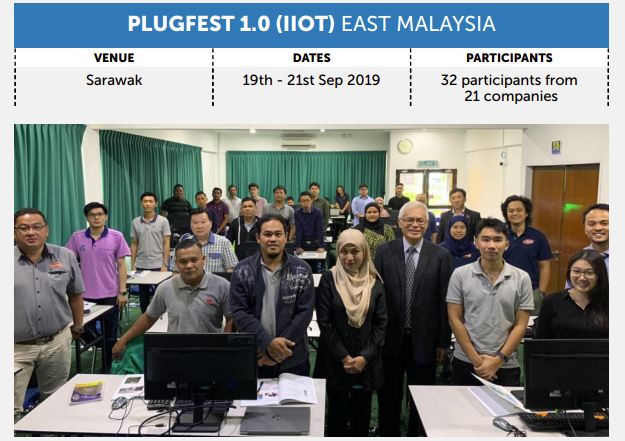

Plugfest 1.0 at Malaysia Productivity Corporation (MPC) Sarawak. PSDC Intel and Axiomtek were working hand in hand in delivering the hands on training with the objective of adoption of industry 4.0 to the industry.

Servomotor battery Backup monitoring at Infieon Kulim

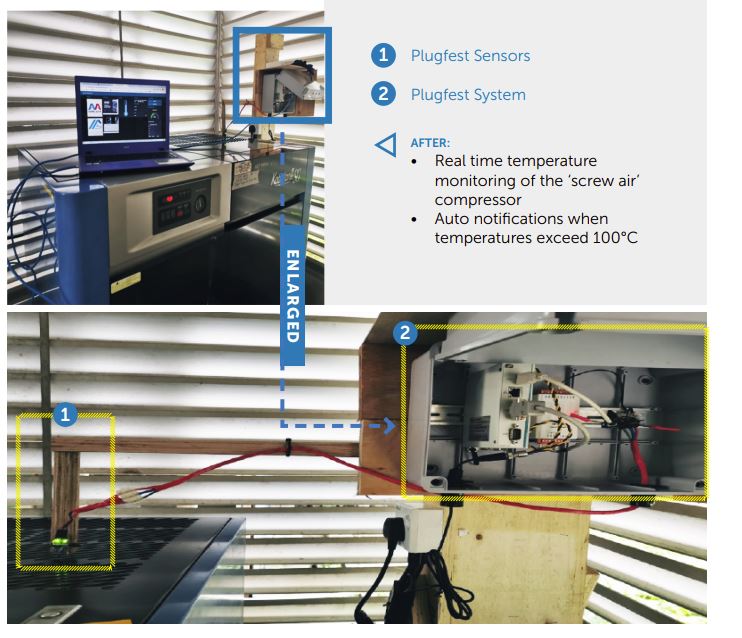

Asteel AJIYA Real Time Temperature monitoring Air compressor

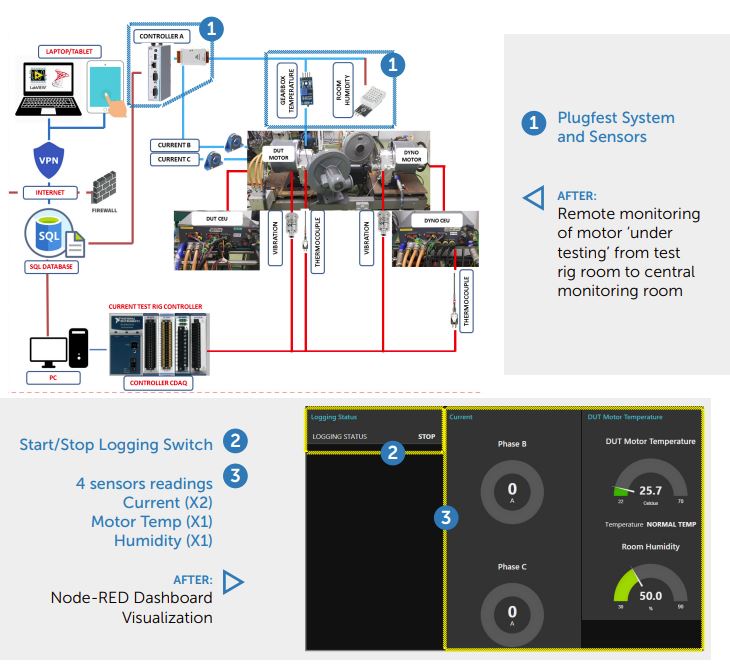

ACM remote Motor test monitoring

Plugfest 2.0 EDGE AI based

Plugfest 2.0: AI-Based IoT for Smarter Manufacturing

Objective: While Plugfest 1.0 introduced IIoT, Plugfest 2.0 expanded into Artificial Intelligence (AI), enabling participants to develop more intelligent systems. The focus of Plugfest 2.0 was AI-based machine vision solutions, allowing participants to automate tasks such as quality control, anomaly detection, and production monitoring.

Key Technologies:

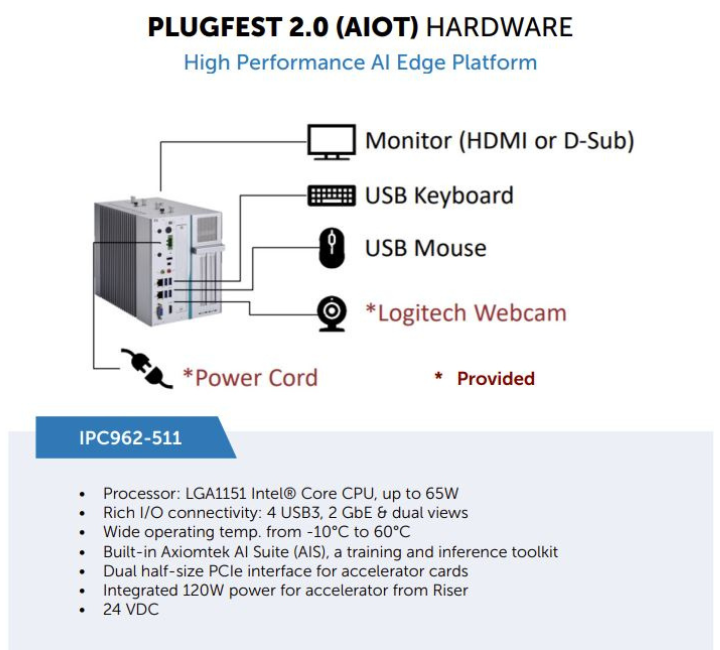

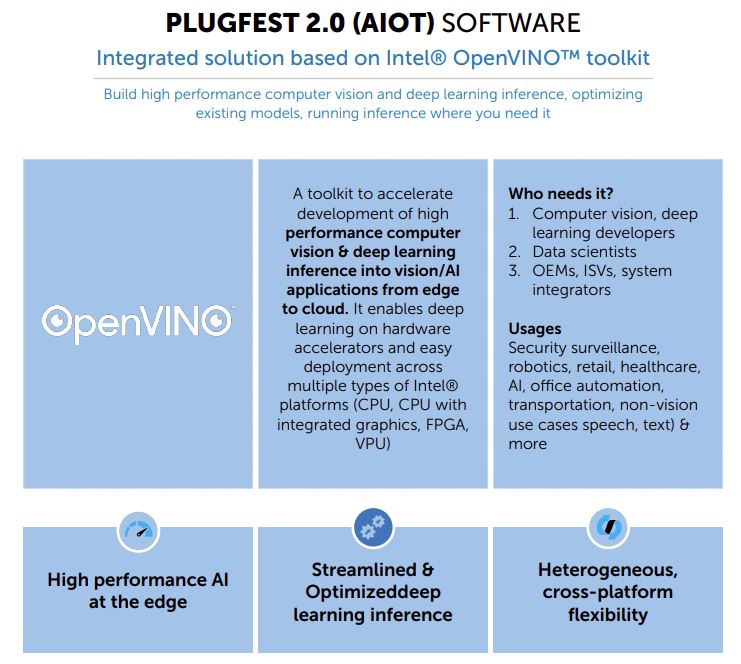

Participants were equipped with an Intel-based industrial PC, preloaded with Intel Edge Insights for Industrial and the Intel OpenVINO toolkit, which provided tools for image detection, machine learning algorithms, and AI-based inferencing.

The six-day workshop covered critical AI topics including image capturing, object detection, labeling systems, and AI model training. Participants learned to apply these technologies to real-world industrial problems such as defect detection in manufacturing.

Axiomtek Malaysia’s Central Role:

Axiomtek’s industrial PCs and AI edge computing platforms were at the core of Plugfest 2.0. These devices were used to run AI inferencing tasks in real-time, demonstrating how AI can enhance production line monitoring and improve overall equipment effectiveness (OEE).

Axiomtek’s hardware enabled fast and efficient processing of large datasets generated by AI-powered sensors, allowing for instant decision-making and reducing the time required for quality inspections.

Real-World Examples:

Using Axiomtek’s platform, participants were able to develop solutions such as automated visual inspection systems that detected defects in products during the production process. For instance, companies could monitor production lines for anomalies such as misaligned parts or faulty packaging, and automatically trigger alerts or corrective actions.

One notable POC involved the detection of faulty components in semiconductor manufacturing, where AI was used to identify defects in microchips, reducing the likelihood of defective products reaching customers.

Deep Learning AI Computer Vision Training

Partner Testimonial : Axiomtek Malaysia

“Plugfest 2.0 (AIOT) workshop is

a very comprehensive training

that provide the participants

a good foundation of

understanding about AI-Vision

applications in the industry,

particularly the Deep learning AI and Inferencing.” by CCLee ( Axiomtek Malaysia GM and founder CEO of AIOTmission Sdn Bhd

Plugfest 2.0 AIOT Software

Axiomtek’s Role in the Evolution of the Plugfest Programs

Although Axiomtek’s contributions were not explicitly highlighted in the official program materials, the company’s hardware and software platforms were integral to the success of both Plugfest 1.0 and Plugfest 2.0. Over time, Axiomtek has refined these programs into a scalable, industrial-grade solution, taking the following steps:

Enhanced AIoT Integration: Axiomtek has integrated its platforms with advanced AIoT (AI + IoT) solutions, combining the power of artificial intelligence with IoT to offer real-time, data-driven insights for smarter decision-making in industrial environments.

Scalability and Adaptability: The company has optimized the solutions demonstrated in the Plugfest workshops to be scalable across industries of varying sizes, allowing both SMEs and large enterprises to deploy IIoT and AIoT solutions cost-effectively.

Practical Industry Applications: Axiomtek has continuously refined its platforms to meet the practical needs of modern industries. Today, the solutions demonstrated in Plugfest are used to optimize manufacturing processes, reduce downtime through predictive maintenance, and improve overall operational efficiency through real-time monitoring of production lines.

A series of Proof of Concept in the manufacturing environment by participants are listed below for your reference.

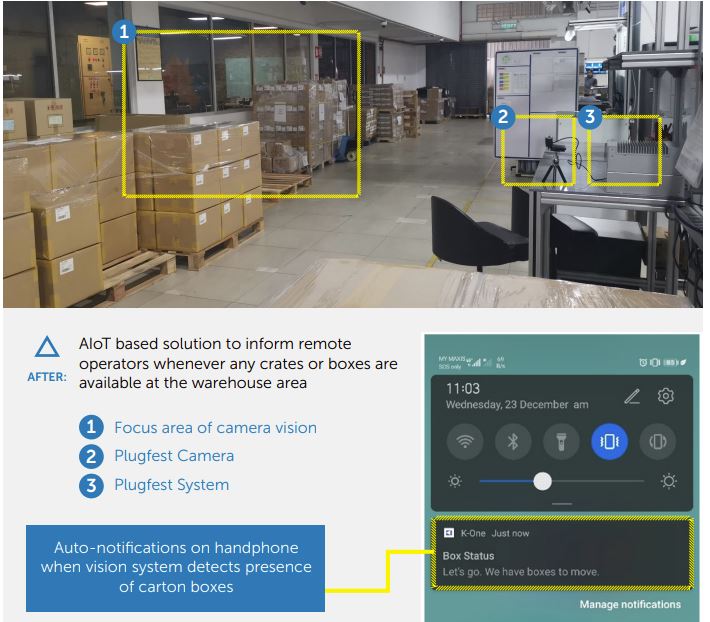

Plugfest 2.0 AI POC on Absent and present by Kone

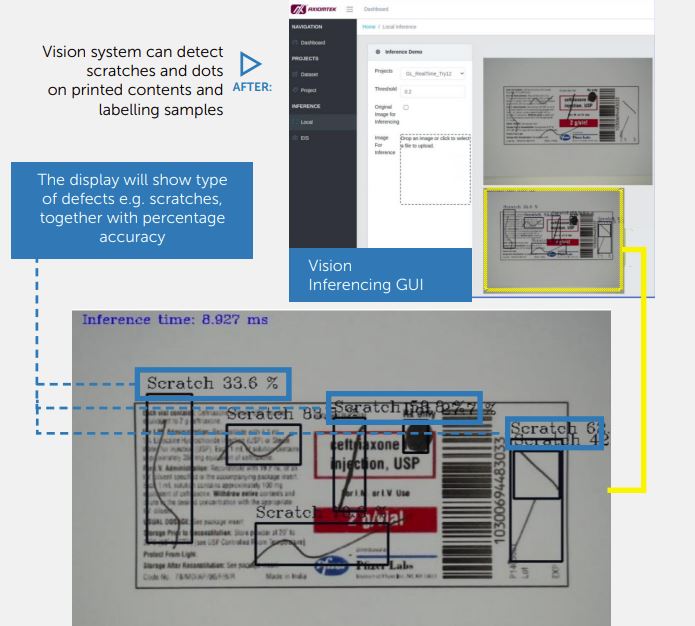

Plugfest 2.0 AI POC on label checking

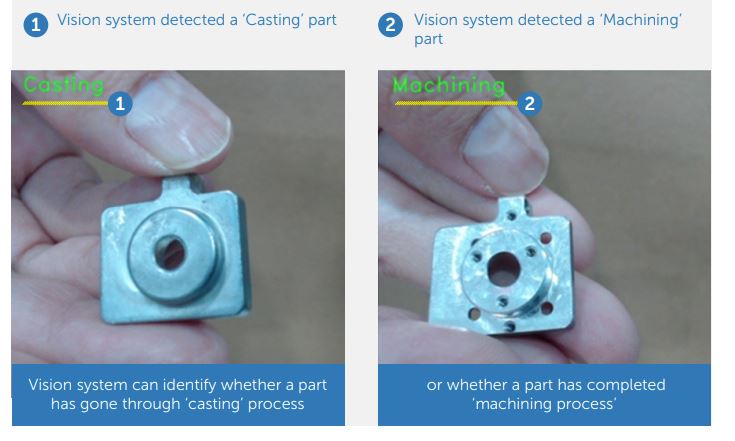

Plugfest 2.0 AI POC on Object Detection

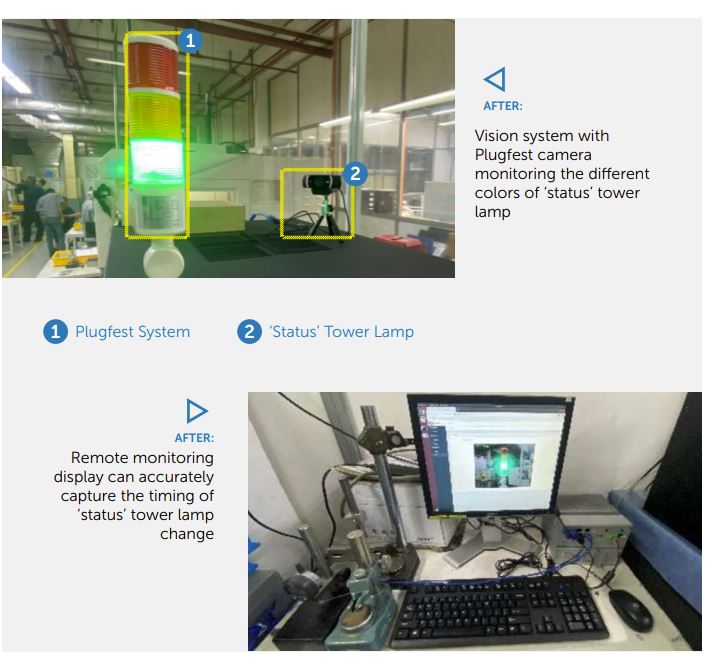

Plugfest 2.0 AI POC on Machine Status

Axiomtek’s Subsidiary: AIoTmission Sdn Bhd

To further extend the impact of the Plugfest programs, Axiomtek has supported the initiative through its subsidiary, AIoTmission Sdn Bhd. This subsidiary is focused on bridging the gap between AI, IoT, and industry, ensuring that Malaysian companies can harness the full potential of Industry 4.0 technologies. By leveraging the knowledge gained in Plugfest 1.0 and 2.0, AIoTmission has continued to provide customized training, support, and deployment services to help SMEs transform their operations using AIoT.

Axiomtek’s Commitment to Malaysia’s Industrial Transformation

Axiomtek’s involvement in the Plugfest programs has played a critical role in driving Malaysia’s Industry 4.0 journey. Through its powerful industrial PCs, edge computing platforms, and AIoT expertise, Axiomtek has enabled Malaysian industries to make significant strides in digital transformation. The company remains committed to refining and scaling these solutions to ensure that they can be applied across a wide range of industries, transforming the way Malaysian companies approach manufacturing and productivity.

Other applications in both the AI and IoT can be realized in the manufacturing environment on OEE Tracking with Stack light tracking modules. In some Smart city applicating AI can be used to track parking space availability via computer vision.

As Malaysia continues its journey toward smart manufacturing, Axiomtek and AIoTmission are poised to remain a key partner in delivering innovative, practical, and scalable solutions that drive industrial transformation.