Integrating aI and IoT for optimal industry 4.0 Performance

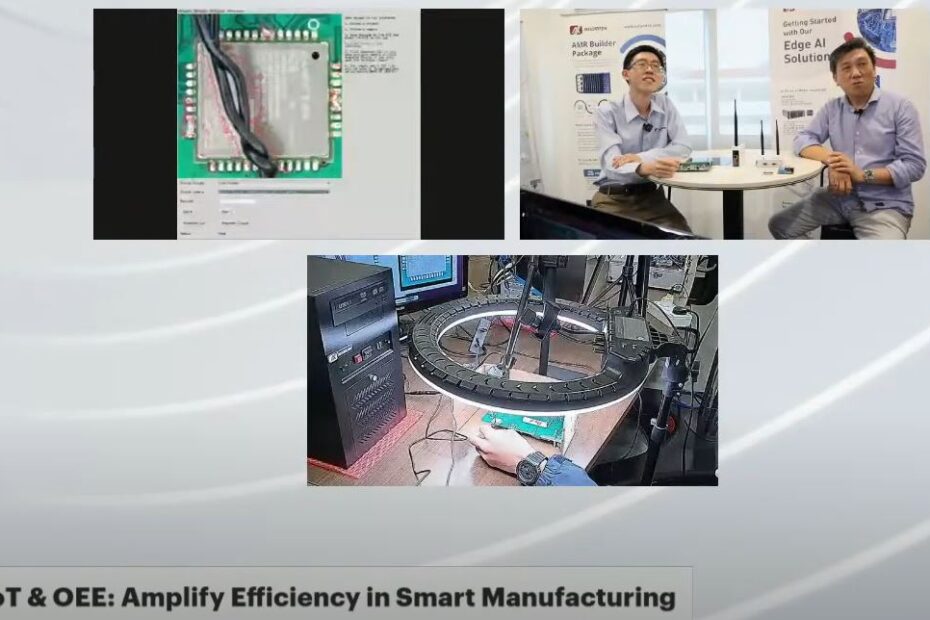

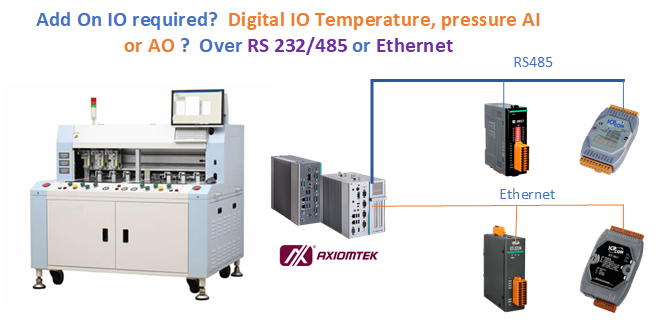

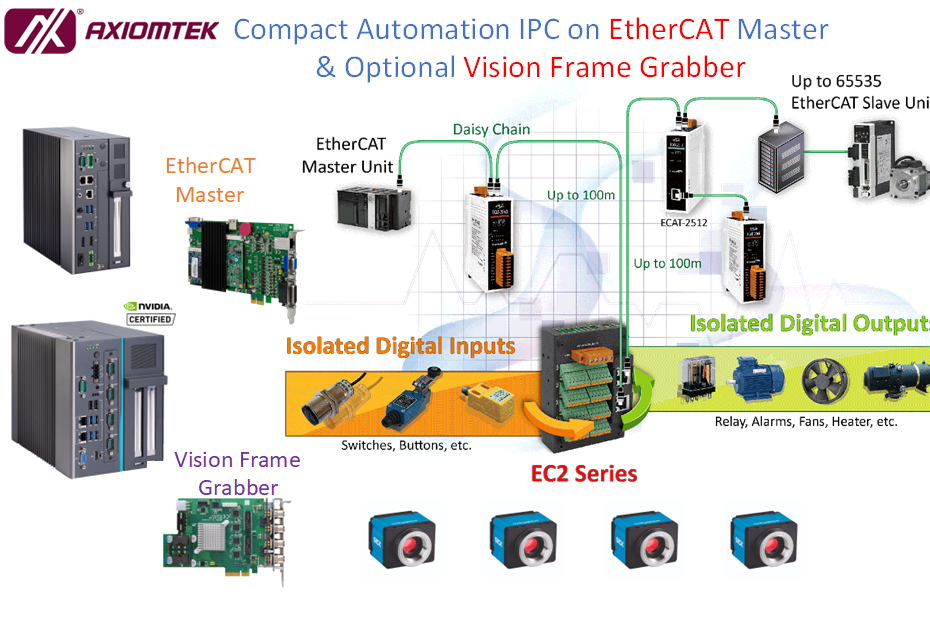

This session of ” Sembang AIoT” talk more about the integrating IIoT and AI for optimal performance of industry 4.0 performance. while IR4 principles lay the foundation for a connected, transparent, and autonomous industrial environment, it is the integration of AI and IoT that actualizes and optimizes these principles to achieve the full potential of Industry 4.0. Industry 4.0 (IR4) is the current trend of automation and data exchange in manufacturing technologies, encompassing cyber-physical systems, the Internet of Things (IoT), cloud computing, and cognitive computing. Here are the four main design principles of Industry 4.0: Interconnection Decentralization Data Transparency Technical Assistant The four fundamental design principles provide a clear framework for Industry 4.0’s goals and future direction. Interconnection and Information Transparency are intrinsically linked to the Internet of Things (IoT), emphasizing the significance of connectivity. Data collected from sensors, machines,… Read More »Integrating aI and IoT for optimal industry 4.0 Performance