Axiomtek Malaysia AIoT Team led by Mr. CC Lee and Tan Kien Leong presented another live session on the 8th of March 2024 again and this is episode number thirty-nine. During the session, we shared the fundamentals of AI in manufacturing. An overview of different types of AI methods and verticals were discussed such as Vision AI, Machine Learning AI for Big Data, LLM ( Large Language model), and Generative AI. What are the types and concepts of AI that can be applicable in Manufacturing? We touched on that in more detail in terms of the Operation level behind the AI process and we set up a demonstration of Axiomtek AIS in Vision AI for the manufacturing process.

The concept of Artificial Intelligence (AI) in the manufacturing industry involves leveraging advanced technologies to create intelligent systems that can perform tasks traditionally requiring human intervention. In manufacturing, AI is applied to enhance efficiency, optimize processes, and make data-driven decisions, leading to a transformative impact on traditional manufacturing processes.

Key aspects of AI in manufacturing include:

Predictive Maintenance:

AI enables the prediction of equipment failures by analyzing data from sensors and machinery. This proactive approach helps minimize downtime and reduce maintenance costs.

Quality Control:

AI systems, especially those utilizing machine learning, can analyze large datasets to identify patterns and anomalies, ensuring high-quality production through real-time quality control and defect detection.

Process Optimization:

AI algorithms analyze production data to optimize manufacturing processes. This can lead to improved resource utilization, reduced waste, and increased overall efficiency.

Supply Chain Management:

AI enhances supply chain operations by providing real-time insights, demand forecasting, and inventory management. This leads to streamlined logistics and better responsiveness to market demands.

Collaborative Robotics (Cobots):

AI-powered robots work alongside human operators, enhancing efficiency and safety. These collaborative robots can perform repetitive tasks, allowing human workers to focus on more complex and strategic activities.

Customized Production:

AI enables mass customization by adapting manufacturing processes to produce customized products efficiently. This is achieved by analyzing customer preferences and adjusting production lines accordingly.

Energy Management:

AI helps optimize energy consumption in manufacturing facilities by analyzing usage patterns and suggesting energy-efficient practices. This contributes to sustainability goals and cost savings.

Data-driven Decision-Making:

AI processes and interprets vast amounts of data, providing actionable insights for informed decision-making. This shift from intuition-based decisions to data-driven strategies is a significant transformation in manufacturing.

The transformative impact of AI in manufacturing is evident in its ability to drive innovation, enhance productivity, and adapt to dynamic market demands. By embracing AI technologies, manufacturers can gain a competitive edge, improve product quality, and respond more effectively to the evolving landscape of the industry.

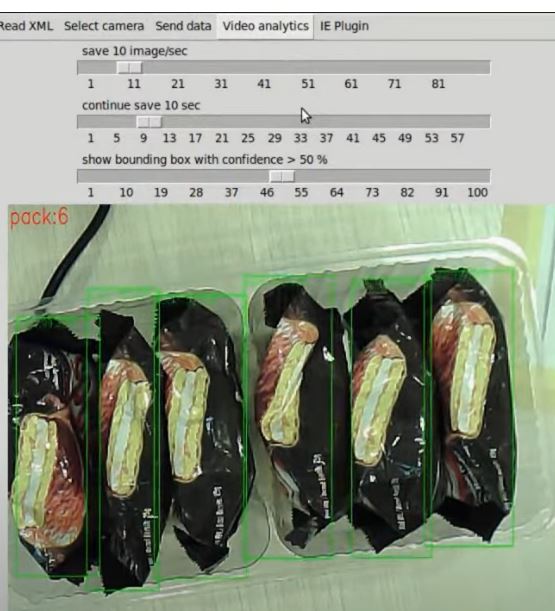

Axiomtek AIS ( The AI Suite) was brought into action in the demonstration of object detection and classification.

Quality control in biscuit packaging process with Vision AI and both the object detection and Classification was demonstrated. Features of Axiomtek AIS :

1. support varieties of industrial cameras

2. Data connectivity to external system or even cloud.

3. Intuitive way to get the AI model trained and build with no coding

4. End to End solution from Deep learning to Inferencing .