AIOT-Driven Power and Energy Monitoring for Smart Manufacturing

In the era of Industry 4.0, where efficiency and sustainability are paramount, the integration of Artificial Intelligence (AI) with the Internet of Things (IoT) has given rise to AIOT—an advanced approach that promises to revolutionize power and energy monitoring in smart manufacturing environments. AIOT combines the power of AI’s predictive and analytical capabilities with IoT’s ability to collect and transmit data, offering manufacturers an unprecedented level of control and insight into their energy consumption.

Objectives of AIOT-Driven Energy Monitoring

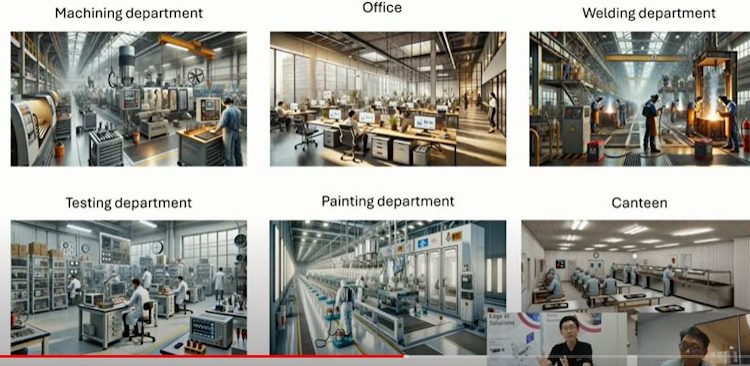

Monitor Plant Energy Consumption: Accurate and real-time monitoring of energy consumption across the manufacturing plant is crucial for identifying inefficiencies and ensuring that energy resources are used effectively.

Map the Efficiency of Departments: By analyzing energy consumption data at the departmental level, it becomes possible to map out which areas of the plant are operating efficiently and which are not. This granular visibility helps in targeted improvements.

Exploit the Potentiality of Energy-Efficient Strategies: Leveraging AIOT allows manufacturers to implement energy-efficient strategies that can significantly reduce energy costs and environmental impact while maintaining or even enhancing production output.

React Promptly at Production Planning and Control Levels: Real-time data and AI-driven insights enable quick decision-making at the production planning and control levels, ensuring that any energy inefficiencies or anomalies are addressed immediately.

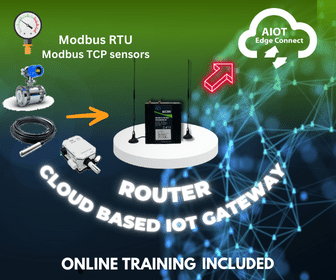

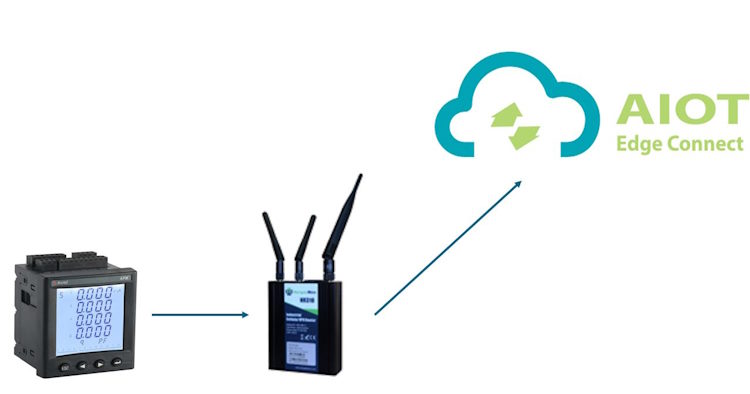

The AEC310 like the picture showed, it can act as one of the mobile IIoT gateway to collect data from power or engery meter. The data captured is then published to the Cloud platform for visualization and AI Data analytic.

Key Components for Achieving These Objectives

To meet these objectives, a comprehensive approach is required, which includes the following components:

Collect, Record, and Visualize Energy Consumption Data: The first step is to deploy IoT sensors throughout the plant to collect data on energy consumption. This data is then recorded and visualized through a centralized dashboard, providing a clear and real-time overview of energy use.

Compute Energy-Related KPIs to Measure Plant Energy Behavior: Key Performance Indicators (KPIs) related to energy consumption, such as energy per unit of production, energy cost per department, and overall plant efficiency, are computed. These KPIs offer a quantitative measure of the plant’s energy behavior.

Integrate Energy and Production Data for Performance Evaluation: By integrating energy data with production data, AIOT systems can evaluate the performance of the plant’s energy efficiency. This integration helps in understanding the relationship between energy consumption and production output, leading to more informed decisions.

Identify Critical Situations for Performance Enhancement: AI algorithms can analyze the collected data to identify critical situations, such as excessive energy consumption in certain departments or times of the day, and suggest actions for performance enhancement.

How AI Can Help in Energy Monitoring

AI plays a critical role in the energy monitoring process, providing advanced functionalities that go beyond traditional monitoring systems:

Anomaly Detection: AI can identify unusual patterns in energy consumption that might indicate inefficiencies, equipment malfunctions, or other issues that need immediate attention. For instance, a sudden spike in energy use during non-operational hours could signal a problem.

Predictive Maintenance: By monitoring power usage patterns, AI can predict when equipment is likely to fail or require maintenance. This predictive capability allows for maintenance to be performed proactively, reducing downtime and preventing costly failures.

Optimization: AI-driven insights help in optimizing energy usage by identifying opportunities for reducing consumption without compromising production efficiency. For example, AI can suggest adjusting machine operating times or optimizing the use of renewable energy sources.

In conclusion, AIOT-driven power and energy monitoring is a powerful tool for smart manufacturing environments, offering the ability to monitor, analyze, and optimize energy consumption at an unprecedented level. By leveraging AIOT, manufacturers can achieve significant cost savings, enhance operational efficiency, and contribute to a more sustainable future.

AIoTmission Sdn Bhd, established in 2022 as a subsidiary of Axiomtek (M) Sdn Bhd, is a leading provider of technological training and consultancy services specializing in Artificial Intelligence (AI) and Industrial Internet of Things (IIoT) solutions. Our mission is to drive the Fourth Industrial Revolution (IR4.0) and facilitate digital transformation across Southeast Asia, including Malaysia, Singapore, Indonesia, the Philippines, Thailand, Vietnam, and Myanmar.

At AIoTmission, we are dedicated to advancing research and development in AI and IIoT technologies, with a focus on industrial applications such as sensors, gateways, wireless communications, machine learning, AI deep learning, and Big Data cloud solutions. Through collaboration with our valued clients and partners, we deliver innovative solutions tailored to industry needs, enhancing technological capabilities and operational efficiency.

The primary focus of the discussion from this live session are mainly technological related especially in the AI and Industrial IOT field which touches the applications in the industries. This session is presented by Mr. CC Lee, our technology trainer and public speaker, along with Mr. Tan Kien Leong, the AIoT trainer and solution architect from AIoTmission.

The primary focus of the discussion was on smart supply chain management utilizing AI and IoT. This topic was presented by Mr. CC Lee, our technology trainer and public speaker, along with Mr. Tan Kien Leong, the AIoT trainer and solution architect from AIoTmission.

Pingback: Unlocking Malaysia's Economic Potential: The Role of Technology

Pingback: Axiomtek AIoT Tech up driving Malaysia's Industry 4.0 Adoption - Axiomtek industrial PC Malaysia

Comments are closed.