-

Features

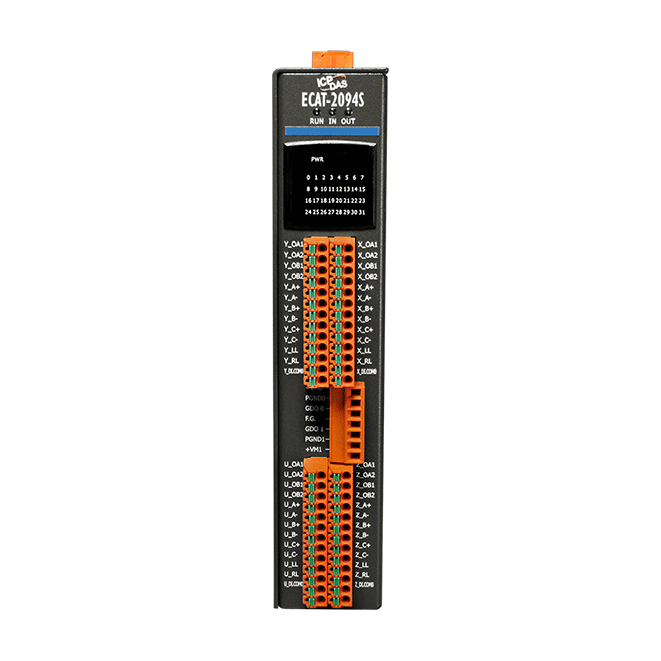

• Supports four stepper motors (2-phase bipolar)

• Stepper motors are controlled in an open loop operation

• Programmable coil current level: up to 1.5 A/phase

• Programmable microstep size: maximum 256 microsteps per full step

• Supported motor voltage range: 6 to 46VDC

• 4 x Encoder interfaces (A, B, Z), differential

• 8 x Digital input. Two DI channels for each axis: reference switch input, latch input

• 2 x Digital output

• Automatic current reduction to reduce heat generation when motor is at standstill

• Drive protection:

‣ Over-temperature

‣ Under voltage

‣ Short circuit

• Optically isolated I/O

• LED indicators for I/O, EtherCAT and motion status

• Internal memory for storing configuration data

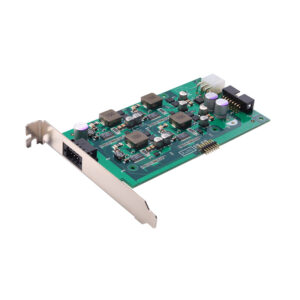

ECAT-2094S 4 axis Stepper Motor driver module

RM100.00

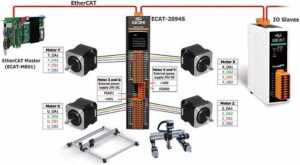

PC-based motion control solution is one of the dominant components in building semiconductor-related machines, namely Automated test handler machine, laser marking machine, Automated tape and rail machines, Test and handler vision inspection machines, etc.

The ECAT-2094S stepper motor controller is a cost-effective, two-phase bipolar stepper driver. The ECAT-2094S simultaneously controls up to four stepper motors. A motor voltage range between 6 and 46V DC and a maximum motor coil current of 1.5A/phase is being supported. For each motor the maximum running coil current, microstep resolution and other motion parameters are software selectable.

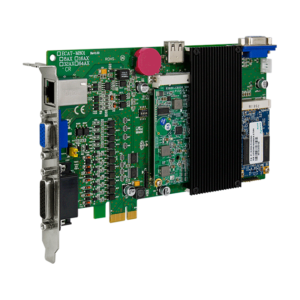

The ECAT-2094S is a standard EtherCAT slave and an EtherCAT master is required to operate the device. The ECAT-2094S supports three operation modes: Free-Run, SM-Synchron and Distributed Clock (DC).

Two-phase bipolar stepper motors can be directly connected to the ECAT-2094S device. The device is designed to operate the stepper motor in an open loop. Configuration has to be done by the EtherCAT master and the application program. Each stepper motor is being independently controlled by a separated driver IC. The four driver ICs are not synchronized and work independently from each other. The driver automatically controls the torque and position of the motor. An integrated ramp generator automatically calculates the acceleration and deceleration distance. In position mode the controller drives the motor to the target position and in velocity mode accelerates the motor to the target velocity. All motion parameters can be changed on the fly.

The ECAT-2094S has four integrated incremental encoder interfaces. Four 32 bit high frequency encoder counter counts the input signal of external incremental encoders. The encoder can for example be used for homing purposes and for consistency checks.

High resolution of up to 256 microsteps per full step is supported for a ensuring smooth and precise motor operation.

For each motor two digital input channels are provided. The digital inputs can be set to act as a simple DI, as a left and right hardware limit switch which automatically stops the motor when activated, or a latch trigger for latching the current motor and encoder position.

The module must be supplied by three power sources. Two motor supply and a 24Vdc control supply. Two motors share one power supply.