“Jom! lets sembang AIoT again“. This is the 19th session of our Live sharing on AIoT and Yes, we continue to bring some practical AIoT approaches and applications with some demonstrations on how you can you realize the power of AIoT in any of your project.

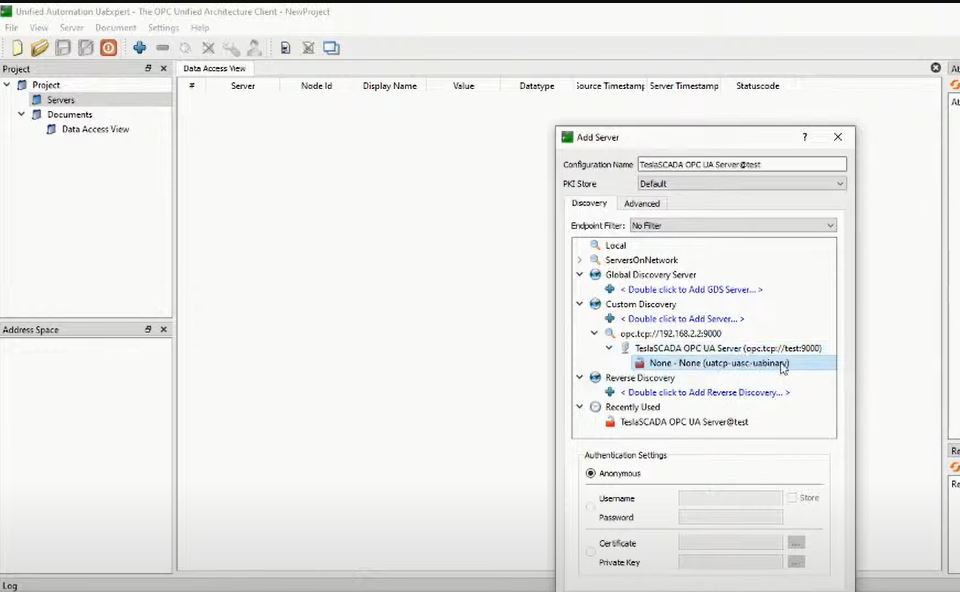

The Vision AI techniques were shown in the live session on building AI data from the Image and how the data is presented during the inferencing was discussed.

There are several ways how AI engine will present you the result:-

1. Marking on the image/ video

2. in text form or wording

3. By way of Audio output.

Above are the fundamental of presenting the AI data. One of the example taken from the moving vehicle on the road. In identifying what is the moving object, the size and the identify can be tracked by AI engine once the AI model is formulated.

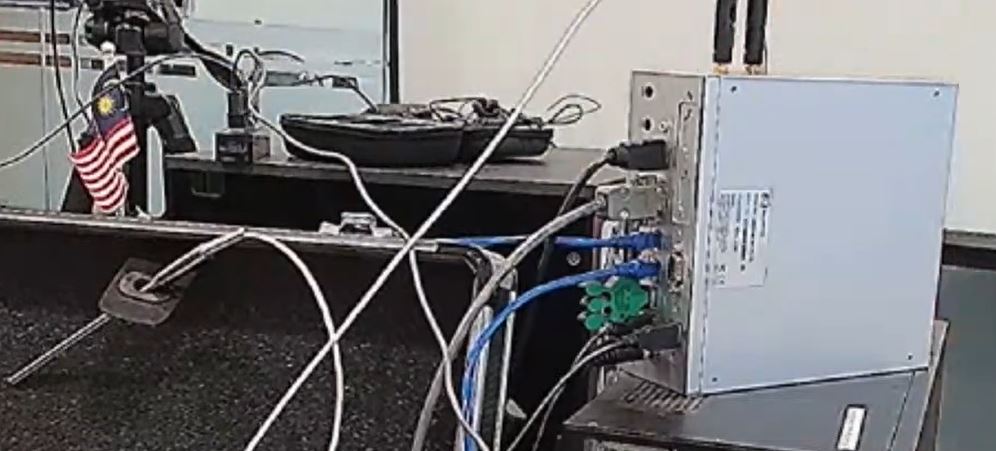

In this case, the computing engine can be of a AI edge system from Axiomtek or a AI server engine that is sitting in the control room.

bounding box is the right word to use where after the inferencing, the AI engine will draw you a bounding box to inform you in visual. In this case, the truck is the identified object.

hear us more from in the youtube channel

https://youtube.com/live/V9dmpCdmY8c

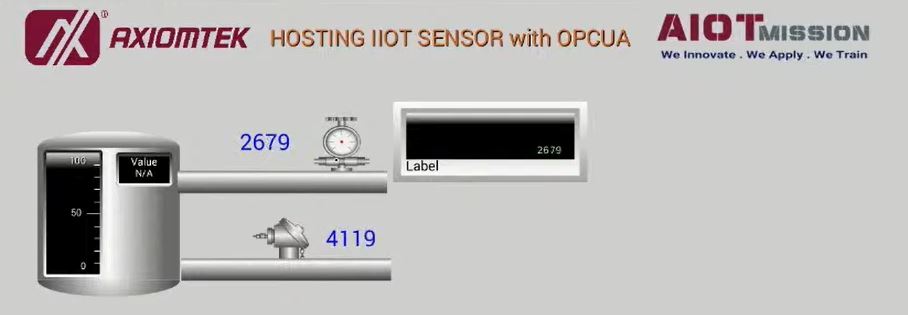

Hosting IIoT sensor data with Axiomtek Edge as OPCUA server

In the 2nd part of the live session, we talked about the the available process controllers, transmitters and analyzers in the industry. These are the IIoT data points that is important in the crucial decision making in running a process control plant.

Two major communication protocol are usually used in this process instrumentation, there are:-

1.Modbus ( Modicon Bus) now Schneider Electric.

Communication standards or buses which is deployed for Modbus communication are:

* TCP/IP over Ethernet

* Asynchronous serial communication in a wide range of standards, technologies: EIA/TIA-232-E, EIA-422, EIA/TIA-485-A, fiber, radio frequency,

2. HART ( Highway Addressable Remote Transducer)

The HART Communication Protocol (Highway Addressable Remote Transducer) is a hybrid analog+digital industrial automation open protocol. Its most notable advantage is that it can communicate over legacy 4–20 mA analog instrumentation current loops, sharing the pair of wires used by the analog-only host systems. HART is widely used in process and instrumentation systems ranging from small automation applications up to highly sophisticated industrial applications.

For Modbus, they are usually easier to integrate to the IIoT gateway, But, for the HART, usually, we require a transceiver or converter from HART to Modbus that allow this sets of HART data to be captured in a good order.

Live demo on the hosting Temperature data from RTD sensors via OPC server ( powered by Axiomtek IIoT edge gateway)

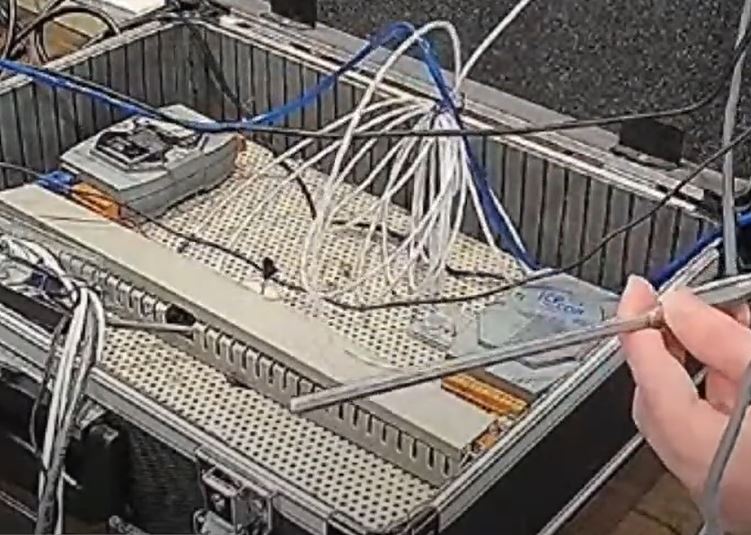

The IIoT embedded SCADA tool was used in making up the data acquisition via Modbus and the RTD temperature module was used to connect directly to RTD sensors

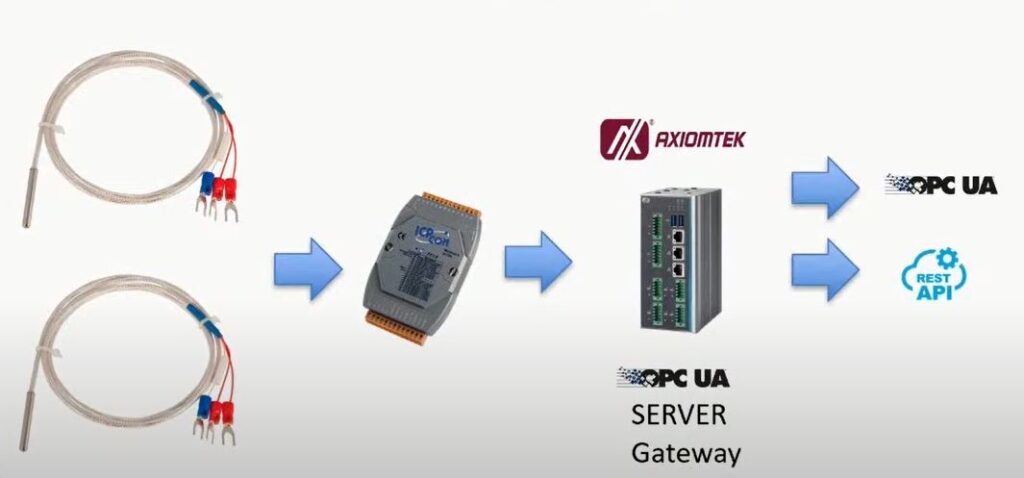

RTD sensor and RTD temperature module that connect to Axiomtek Edge Gateway and the OPC server is hosted at the gateway for external OPCUA Client to connect.

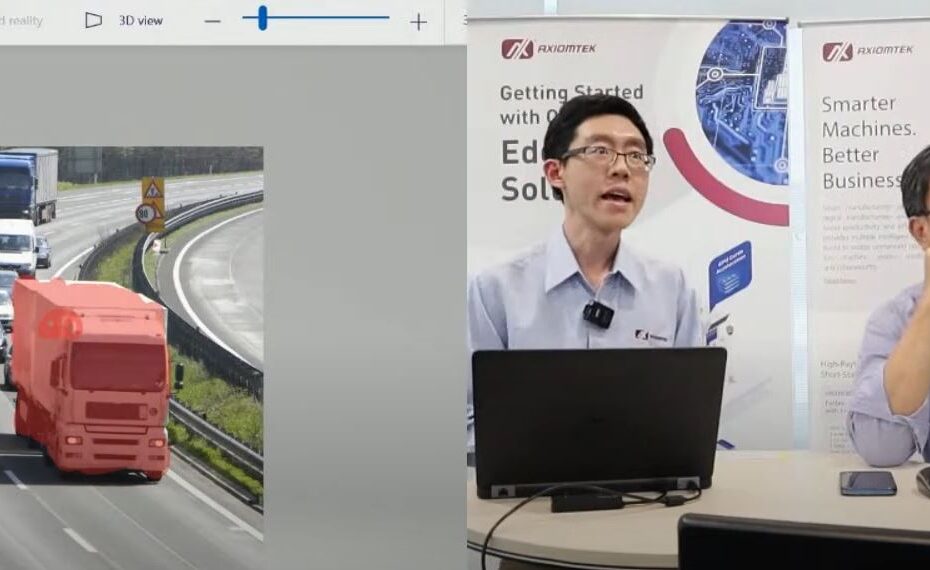

Unified Automation OPCUA client connection to the OPCUA server

The Demonstration of OPC UA server started with the configuration of the the RTD sensor module to connect with the local embedded SCADA station as as a gateway where all data collected via Modbus interface. The data is then shared over OPCUA server with the configuration of OPCuA to host the data for other OPCUA client to connect.

The unified Automation OPCUA client ( a third party OPCUA client) is used to connected the OPCUA server that is running on the Axiomtek Edge gateway as opcuA server.

To see the whole demo, please go to our Youtube channel below for full demonstration.

Pingback: Building a On Premise LLM Server with Axiomtek SERVER - Axiomtek industrial PC Malaysia

Comments are closed.