Sembang AIoT 18 sharing session kick started with the AI model building essential where Kien Leong shared the importance of the Dataset augmentation in computer vision AI.

Recalling the Axiomtek AIS ( AI suite) used during the plug fest II where Axiomtek AIS was used in the training program organized by Malaysia Productivity Centre and EEPN, AIS equipped with the the

Dataset augmentation function where the collected dataset was scrambled to go through the augmentation process so as to train the Model to deep learn the different possibilities and combinations of appearance.

We managed to insert a short Demonstration on the computer vision AI on the work space Safety where the AI was used in checking the compliance like the wearing of Helmet, Vest and etc.

The workspace AI was running in one of the Axiomtek AI edge / IPC.

Several challenges was discussed in the session where dataset from the site is crucial to determine the accuracy of the judgement by the AI model. Watch this recorded live session to find out more.

Pressure sensors in IIoT

The pressure, an important process parameter that require accurate measurement must not be forgotten in one of the IIoT sensors where it is widely used in the industries.

We highlighted two types of commonly used sensor namely, Strain gauge sensors and Piezoelectric sensors. These sensors are used in many instrument and apparatus.

Piezoelectric Sensor:

Principle: Piezoelectricity is the electric charge that accumulates in certain solid materials (like crystals, certain ceramics, and biological matter like bone) in response to applied mechanical stress. The word “piezoelectricity” means electricity resulting from pressure.

Function: When pressure is applied to a piezoelectric material, it generates a voltage proportional to that pressure. This voltage can then be measured and used to determine the amount of pressure applied.

Applications: Due to their ability to respond to fast changes in pressure, piezoelectric sensors are often used in dynamic applications. They are found in many applications including:

Measuring dynamic pressure changes in gases and liquids.

Detecting the force of impact in automotive airbag systems.

In musical pickups, especially for acoustic instruments.

In some microphones to detect sound waves.

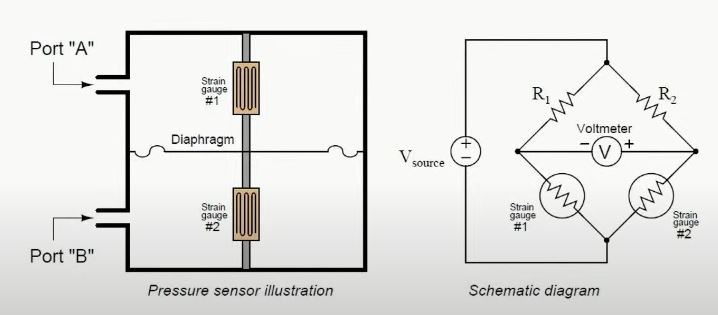

Strain Gauge Pressure Sensors:

Principle: A strain gauge consists of a conductive pattern (often made of a metallic foil) that is affixed to a flexible backing. When this pattern is stretched or compressed, its electrical resistance changes.

Function: When pressure is exerted on a diaphragm or membrane, it deforms (or strains). A strain gauge attached to this diaphragm will also deform, leading to a change in its resistance. This change in resistance is proportional to the pressure exerted on the diaphragm. By measuring this change in resistance, the applied pressure can be determined.

Applications: Strain gauge pressure sensors are widely used due to their reliability and stability. They are found in various applications including:

Industrial process monitoring and control.

Aerospace and automotive sensors.

Medical devices for monitoring blood or fluid pressures.

Load cells for weight measurement.

Both types of sensors come with their own sets of advantages and limitations. While piezoelectric sensors excel at measuring dynamic pressures over short durations, strain gauge sensors are often preferred for stable, continuous pressure measurements.

One of the interesting part of the pressure is about the different pressure sensors where the electronics bridge circuit is used to measure difference of pressure from the 2 strain sensors where the potential different is monitored and captured.

To watch and hear more from us, do subscribe to watch this youtube channel. It will be held every Friday of each week. See the link and video below:- or click the link below

https://youtube.com/live/NEgPh7CxYhs

We at Axiomtek offer a 2 hours free AIoT workshop, a hands on workshop that shouldn’t missed.

scan the QR code to preregister with us. we will notify you when the workshop is open.

Pingback: AI edge Facial recognition for workspace safety - Axiomtek industrial PC Malaysia

Comments are closed.