During the Sembang AIoT live session, we shared one of the Malaysia IoT Association’s events that we attended on empowering ESG with IoT.

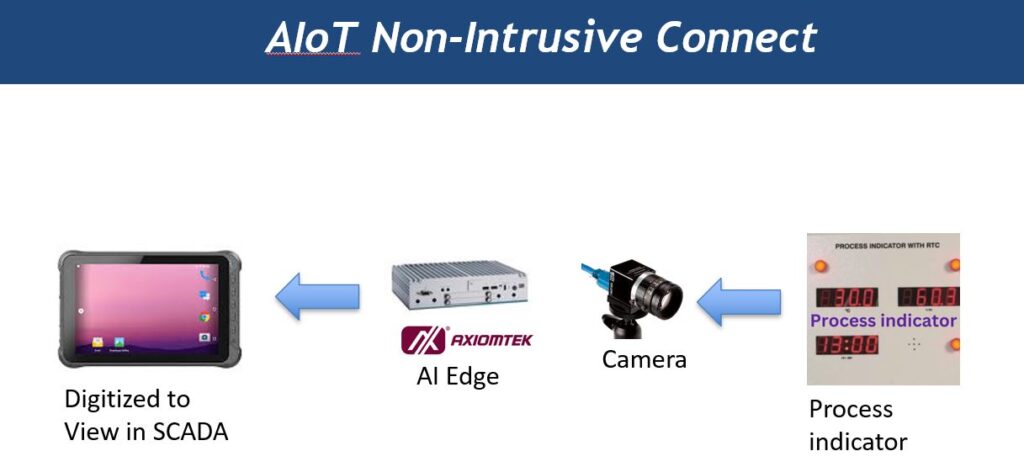

Once again non-intrusive data extraction with AI was brought up in the presentation. It is a shortcut to extract important data more easily with either a camera or the video extracted from the existing system. Legacy systems with operating system like DOS, Windows XP, and Win 2000 that run in most of the old machine is not easy to extract. Usually, it requires substantial effort in programming and integration. AIoT Non-Intrusive Connect solution comes with the system display interception device and then fed to the AI engine to translate the video into Digital data. The extracted Data can be easily shared over API calls, MQTT, or text files. Of course with AIoT edge connect cloud platform or any third-party IoT cloud platform, the data can be configured to be published there.

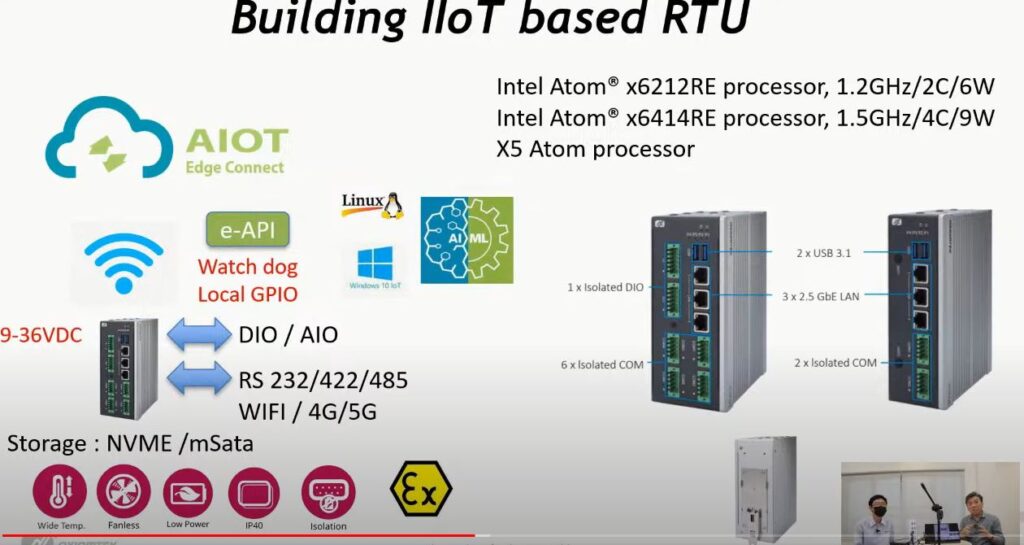

A Remote Terminal Unit (RTU) is a specialized device used in industrial control systems to monitor and manage remote equipment. It plays a crucial role in supervisory control and data acquisition (SCADA) systems, which are used in various industries such as manufacturing, energy, water treatment, and more.

Key features of an RTU include:

1. Remote Monitoring: RTUs are placed in remote locations to monitor and collect data from sensors and devices. These sensors could measure parameters like temperature, pressure, flow rates, voltage, or other relevant data depending on the application.

2. Data Acquisition: RTUs are equipped with input channels to collect analog and digital data from field devices. They convert this data into a digital format for transmission and processing.

3. Control Functions: In addition to monitoring, some RTUs also have control capabilities. They can send commands to remote devices, such as turning equipment on or off, adjusting settings, or executing specific actions based on the data they receive.

4. Communication: RTUs communicate with a central control system or a master station, usually located at a central facility. Common communication protocols include Modbus, DNP3 (Distributed Network Protocol), and others, depending on the industry standards and requirements.

5. Real-time Operation: RTUs are designed to operate in real-time, ensuring timely and accurate data acquisition and control.

6. Reliability and Environmental Resistance: Since RTUs are often deployed in harsh environments, they are designed to be robust and resistant to environmental factors such as extreme temperatures, humidity, and vibrations.

RTUs are a crucial component in the automation and control of processes in industries where remote monitoring and control are essential. They enable efficient management of distributed systems by providing a link between field devices and the central control system, allowing operators to make informed decisions and respond to changes in the environment or process.

As you can see, the RTU still stay a valid and important equipment in the process control especially at the remote area. In the sembang AIoT live session, we shared the building block of RTU, How Axiomtek’s ICO hardware+ IIoT software tools can be used to build a reliable RTU system that serve the industry.

Non Intrusive data extraction with AI

Tapping data from the process plant can be a big challenge. In order to perform data extraction from the process display, big effort is required such as adding additional components, re adjustment of sensors, reconfigure some setting and rewiring with testing of commissioning. It is not only the work and cost of the downtime can be substantial.

We presented the non intrusive data extract demonstration with some process display and the data extracted is shared over a SCADA interface that can be viewed at the Ruggedized tablet.

We invite you to subscribe to our ” Jom lets Sembang AIoT” You Tube channel and you can watch us video there at this link: –

https://www.youtube.com/watch?v=fK-coJE84z8