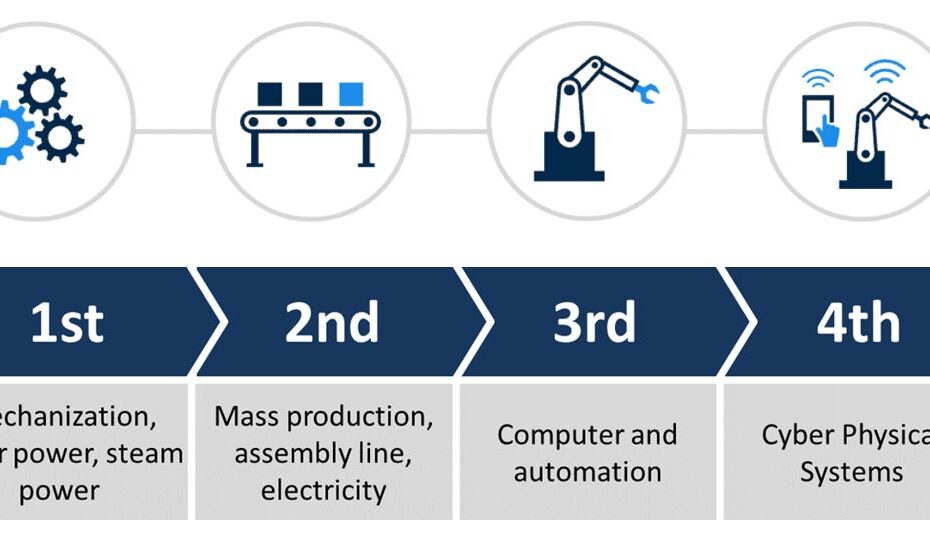

In the recent ” Sembang AIoT” session, Mr. CC Lee and Kien Leong from Axiomtek Malaysia did a deep dive into the fundamentals of Industry 4.0. The history of the Industrial Revolution was discussed and the basic principles of IR4 were discussed.

Industrial Revolution 1.0: The Age of Mechanical Production with Steam Engine

The first industrial revolution, which began in the late 18th century, marked the shift from agrarian and manual labor-based economies to mechanized, factory-based production. Key innovations included the steam engine, textile machinery, and iron production. This era revolutionized manufacturing processes, leading to increased efficiency and the rise of factories.

Industrial Revolution 2.0: The Age of Mass Production with Electricity

The second industrial revolution, spanning the late 19th to early 20th century, introduced electrification and the assembly line. The development of the telegraph and the expansion of railroads further accelerated communication and transportation. Mass production became a hallmark, transforming industries and economies globally.

Industrial Revolution 3.0: The Age of Automation and Computers

The third industrial revolution emerged in the mid-20th century with the advent of computers, automation, and digital technologies. Electronics, telecommunications, and the rise of computing power enabled more sophisticated and precise control over industrial processes. This era saw the integration of computers into manufacturing, leading to improved efficiency and quality control.

Industrial Revolution 4.0: The Age of Smart Manufacturing

The fourth industrial revolution, also known as Industry 4.0, is the current era characterized by the integration of digital technologies, the Internet of Things (IoT), artificial intelligence (AI), and data analytics. This revolution is reshaping industries through interconnected and intelligent systems. Smart factories, predictive maintenance, and decentralized decision-making are key features, driving innovation, efficiency, and flexibility in manufacturing processes.

Key Design principles of Industry 4.0:

Interconnectivity: Devices and systems are interconnected, facilitating real-time data exchange.

Information Transparency: Real-time data provides visibility and insights across the entire value chain.

Technical Assistance: AI and Machine Learning enable machines to make intelligent decisions and adapt to changing conditions.

Decentralized Decision-Making: Autonomous decision-making at the component level enhances agility and adaptability.

The ongoing Industry 4.0 revolution is transforming industries, offering new possibilities for efficiency, sustainability, and innovation. Embracing the latest technologies is essential for companies to stay competitive in this era of smart manufacturing.

Axiomtek Industrial IoT gateway

The latest ICO120 IIoT gateway was brought one the table and the sharing was on the previous version of ICO120 and the latest version where the latest version support HMDI port with all others IO remain the same. Node Red development tools is one of the bundled where Axiomtek provides the Ax-EAPI that allows nodes Read users to access the internal hardware information directly like the health status of the gateway, Onboard digital IOs, Watch Dog functions etc. All those features make the gateway more dedicated IIoT gateway and allow it to serve in many industries.

current version of ICO120 bundles with Ubuntu Linux 20.04 + Node-Red development platform or an Embedded SCADA Runtime that allow an open data capture protocol from many different sensors to PLCs.

In the Application of the Smart Manufacturing, OEE tracking is a most commonly applied system that helps to improve efficiency in the area of quality and productivity.

The Axiomtek IoT gate has been deployed in many of the production facility to achieve this objectives. To ease out the deployment, Axiomtek Malaysia has created this AIoT OEE Connect that comes with the Training powered by AIoTmission the Training division of the Axiomtek Malaysia that provides you an end to end solution in the production OEE tracking.

To watch the live session, visit our Youtube channel at :-

https://www.youtube.com/watch?v=pqX8x2ix050