Introduction

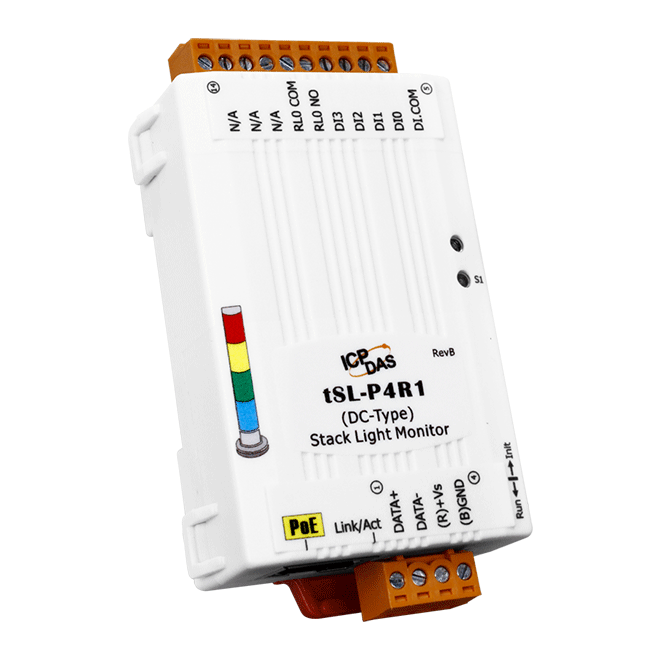

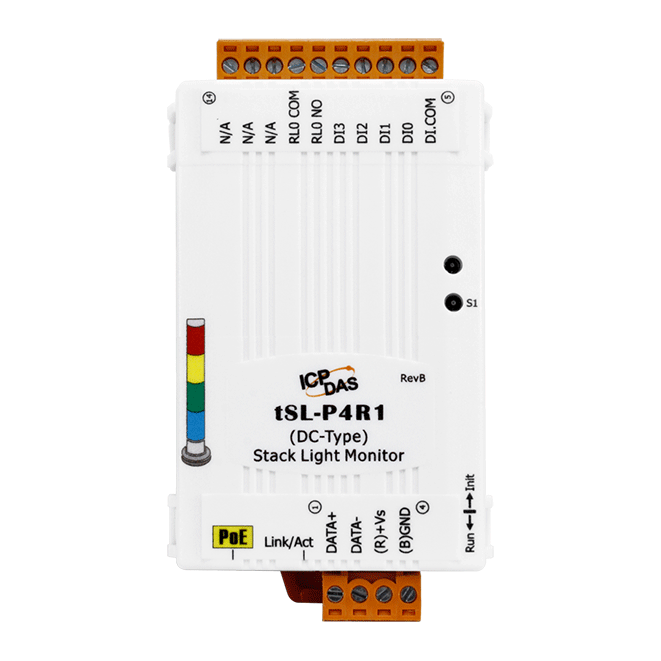

The tSL-P4R1 is a stack light monitoring module which includes 4-channel DC digital input and 1-channel relay output that can be used to monitor the status of the stack light of the MES (Manufacturing Execution System) machine. The module can be used to detect the status of each color segment of the stack light as being either OFF, ON, or flashing. In addition to detecting the status of each individual color segment, the status of the combination of multiple color segments can also be defined, including the ability to report the duration of the previous status. By integrating the tSL-P4R1 module into your system, it is easy to implement stack light status monitoring on an MES via SCADA software to improve machine utilization and throughput.

Applications

- Factory Automation

- Machine Automation

- Remote Maintenance

- Remote Diagnosis

- Testing Equipment